Quality System Certification

We hold the certification of its quality management system compliant with ISO 13485:2016. It is an internationally recognized quality management system standard that served as an aid in supporting compliance with the Medical Device Directive. We place considerable emphasis on following standard procedures with sufficient quality records and integrating well-developed quality management systems into our daily operation. It secures consistency in our products and services and also boosts the confidence of our partners to grow business with higher customer satisfaction ratings.

Incoming Quality Control

We have well-trained IQC workers to conduct incoming quality control upon receiving. With the IQC management system and in-house testing equipment to verify whether the size, appearance, hardness, thickness of raw materials, and components meet our requirements of the product’s intended application before processing.

In-progress Quality Control

In-progress quality control is essential to monitor the production process. Our IPQC will approve the first article before processing, conduct spot check every two hours, and inspect semi-finished products per AQL before hand-over to the warehouse with the application of processing regulation and the in-progress quality system.

Final Quality Control

Before assembly, the first article will be made by a skilled worker, as per assembly instruction and packaging instructions, and approved by the FQC worker before mass production.

Before packaging, FQC inspects every piece in the line to check the appearance, function, dimension, etc. per inspection standards for finished products and to keep records on time. If major defects happen or the same defective issue happens continuously, the cell leader will report it to the supervisor for an immediate solution.

Outgoing Quality Control

01

Appearance

The first impression is everything. We understand how the appearance of a product could affect how likable the product is to customers. With a better brand image for you, products are carefully inspected by our professional QC workers to make sure appearance is consistent with your demands.

02

Dimension

The dimension requirements vary across different items. At Genteel, the dimensions required closer attention during the final inspection are well defined on inspection standards for awareness and are carefully measured by our experienced inspectors with a detailed record on the OQC report for traceability.

03

Function

We know the concerns of our customers for function. Functional inspections are crucial here at Genteel, and our inspectors will inspect according to the expected application of the product specified in the finished product inspection standard.

04

Packaging

We are aware that packaging is a critical factor in product satisfaction. At Genteel, packaging inspections are conducted seriously to make sure the product package is according to the packaging working instructions, with correct printing in the appointed position and all the protective materials added in the right place to ensure proper protection of products during transportation.

Advanced Testing Lab

Product safety is crucial at Genteel. We utilize all kinds of inspection equipment and train professional testers to ensure that our products strictly tested in-house.

In the product design and development stage, we will verify that the product meets the legal standards of the target market.

In the quality control stage, we will arrange the chemical analysis test, physical property test, and mechanical property test of materials and components.

In the mass production phase, we will select the product according to the annual test plan to arrange the reliability test of the finished product and verify that the product continues to meet the design standards and regulatory requirements.

0

/

0

Spectrum Analyzer

Automated Digital Image Measuring Instrument

Fatigue Testing Machine

Wheel Fatigue Testing Machine

Universal Testing Machine

Programmable Temperature and Humidity Test Chamber

Salt Spray Testing

Digital Hardness Tester

Energy Dispersive X Fluorescence Analyzer

Ink Colorfastness Tester

Bursting Strength Tester

Slope for Stability Test

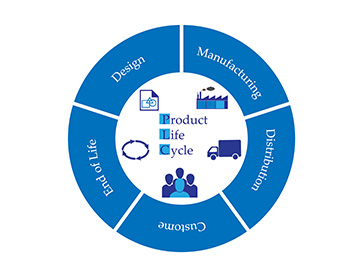

Information System Management

Genteel attaches great importance to and vigorously promote the information construction, now, our BI system through the integration of ERP, PLM, BPM, HR, CRM, QC, and other systems, generating many analysis report forms. Our managers can make full use of information management and control methods as a supporting role in the production, finance, R & D design, Customer Service, human resources, storage and logistics, quality assurance, and so on.

0

/

0

PLM

Barcode System

CRM

BPM

QC System

ERP

BI

MES

Searching For A Reliable Manufacturer ?